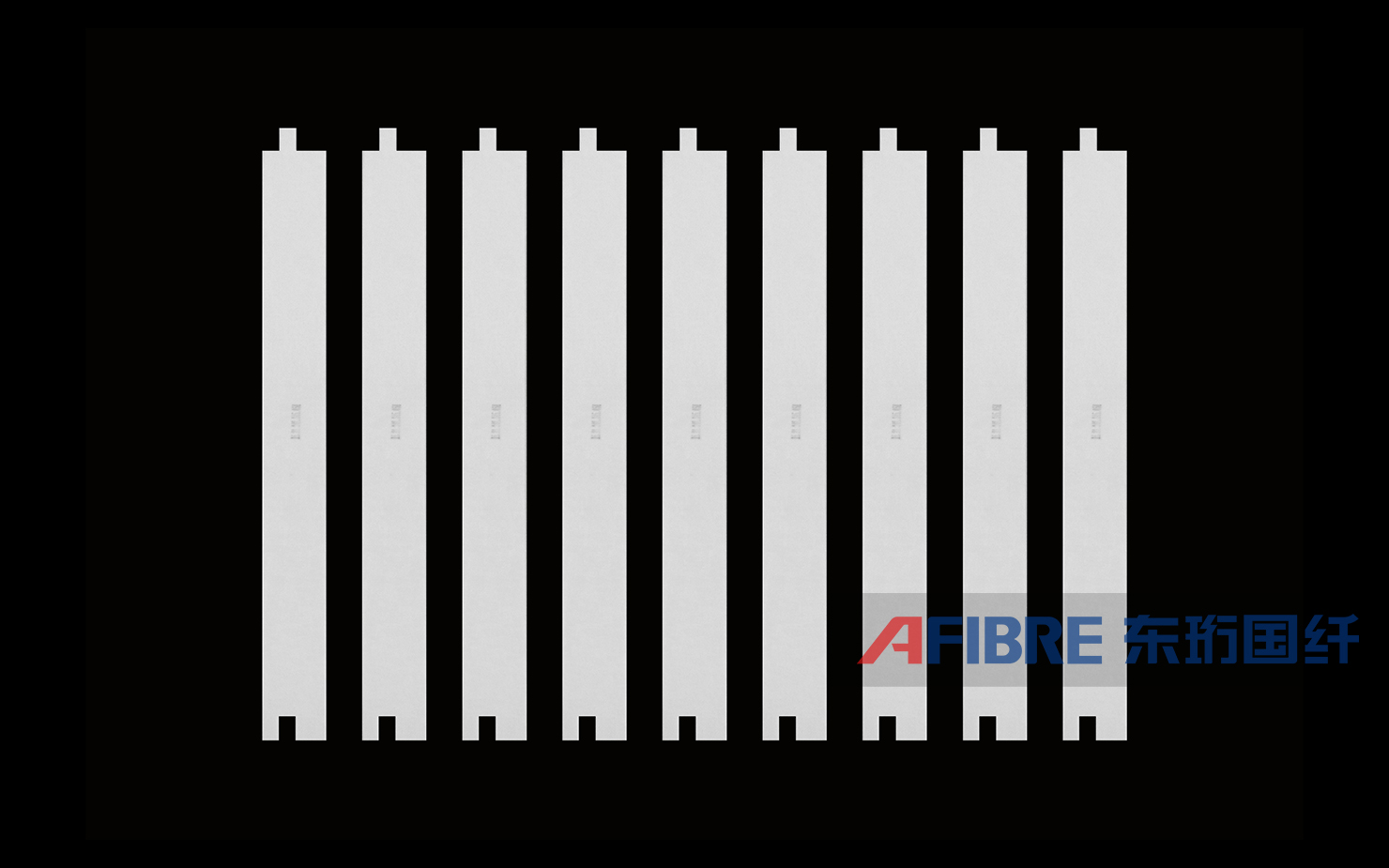

Alumina fibre felt

It is now widely used as a gasket material for automotive three-way catalytic converter, and can adapt to various packaging technologies currently used, and can provide customized design solutions.

72type-F Polycrystalline Alumina Fibre

◇ Chemical composition (%) : AI2O3: SiO2 72-75:25-28

◇ Mineral structure: δ or δ+ Mullite

◇ Classification temperature (℃): 1200 ℃

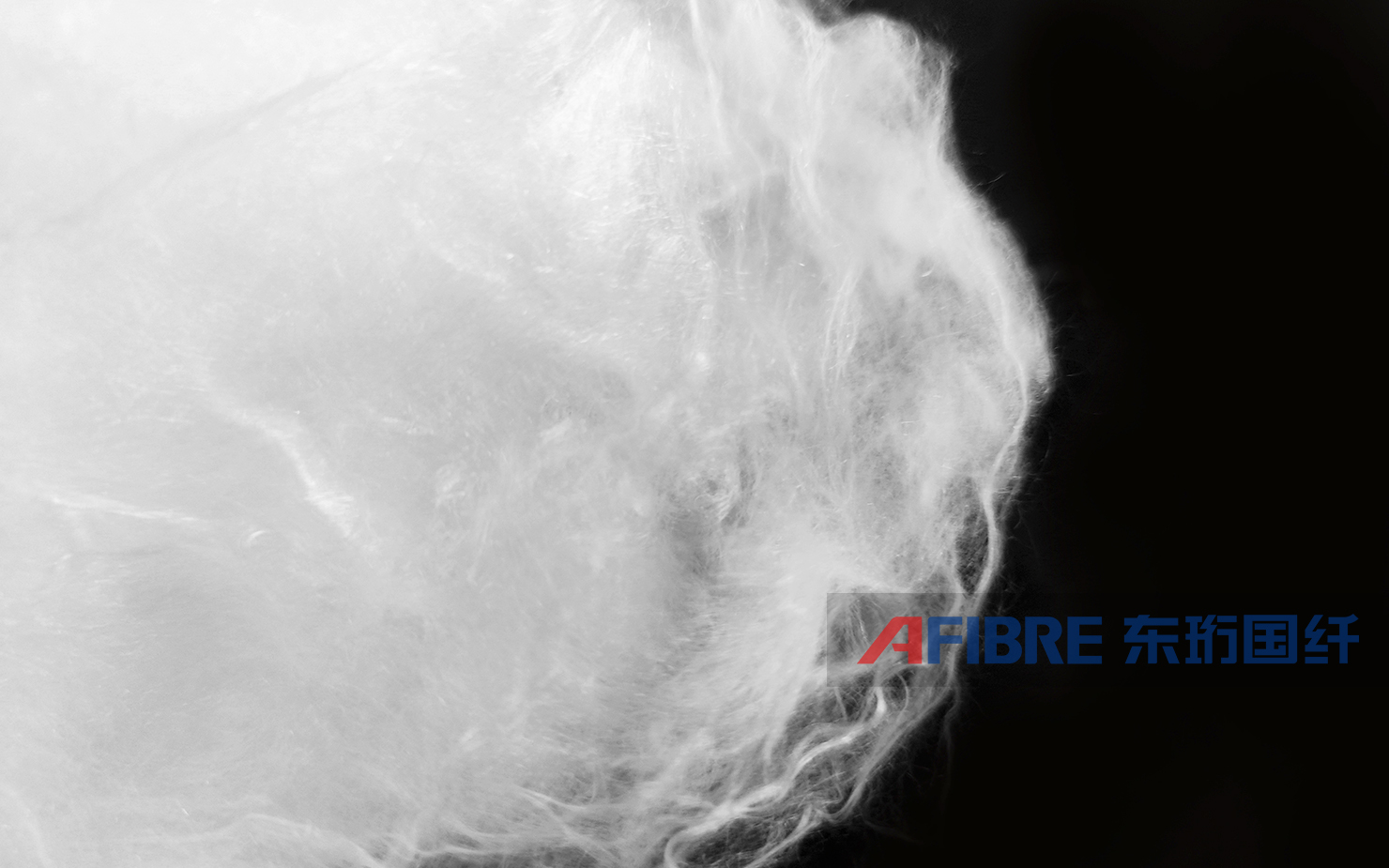

Alumina fibre needled blanket

Alumina fibre needling blanket is made from alumina fibre prepared by sol-gel method through complex needling process.

72type-M Polycrystalline Alumina Fibre

◇ Chemical composition (%) : AI2O3: SiO2 72-75:25-28

◇ Mineral structure: δ or δ+ Mullite

◇ Classification temperature (℃): 1200 ℃

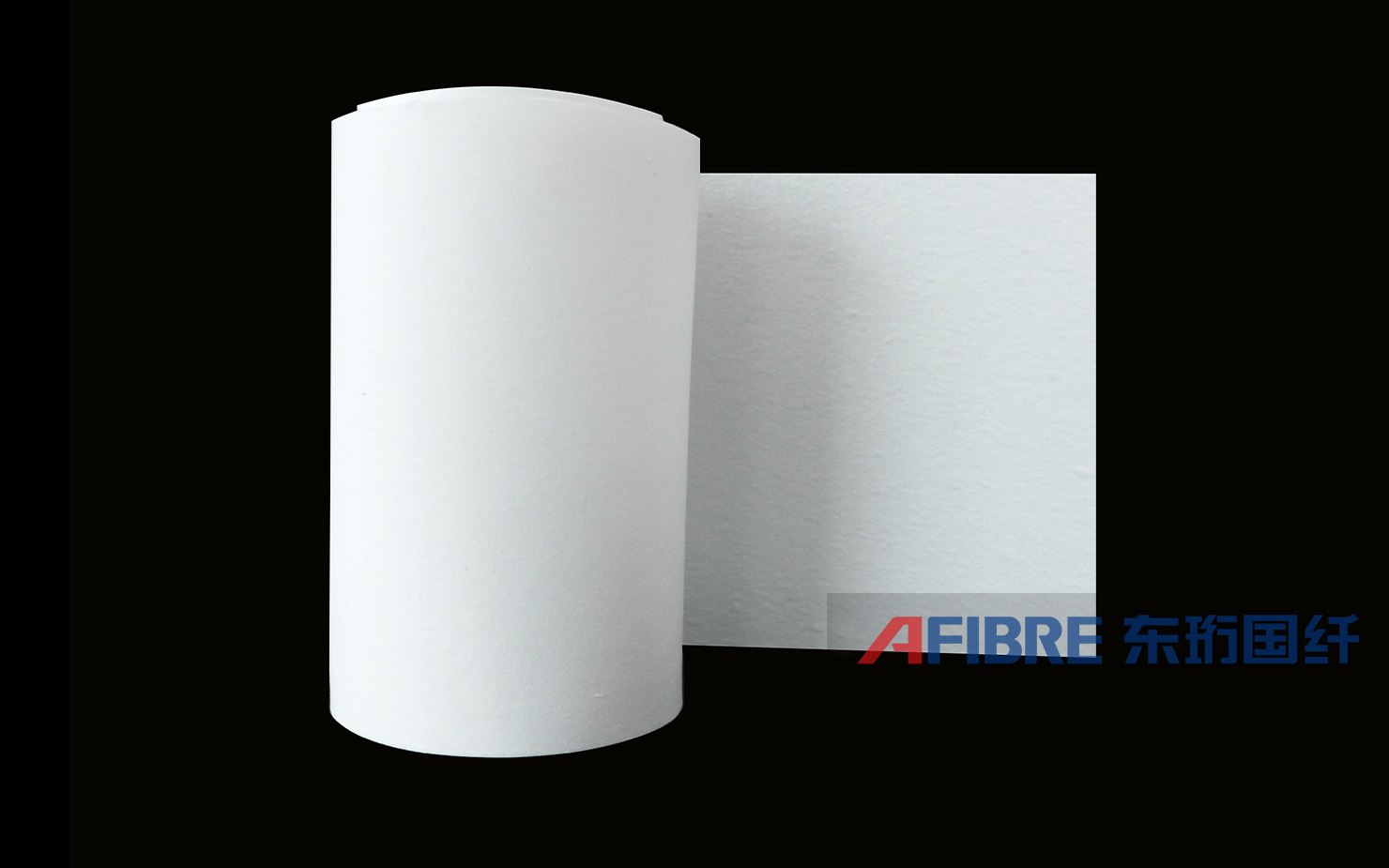

Alumina fibre paper

FP polycrystalline alumina fibre paper is mainly made of polycrystalline alumina fibre and binder, with advanced flame retardance property, heat-insulating property, electrical insulation property

85 type Polycrystalline Alumina Fibre

◇ Chemical composition: AI2O3: SiO2 (%) 85-88:12-15

◇ Mineral structure: mullite+ α

◇ Classification temperature (℃):1700℃

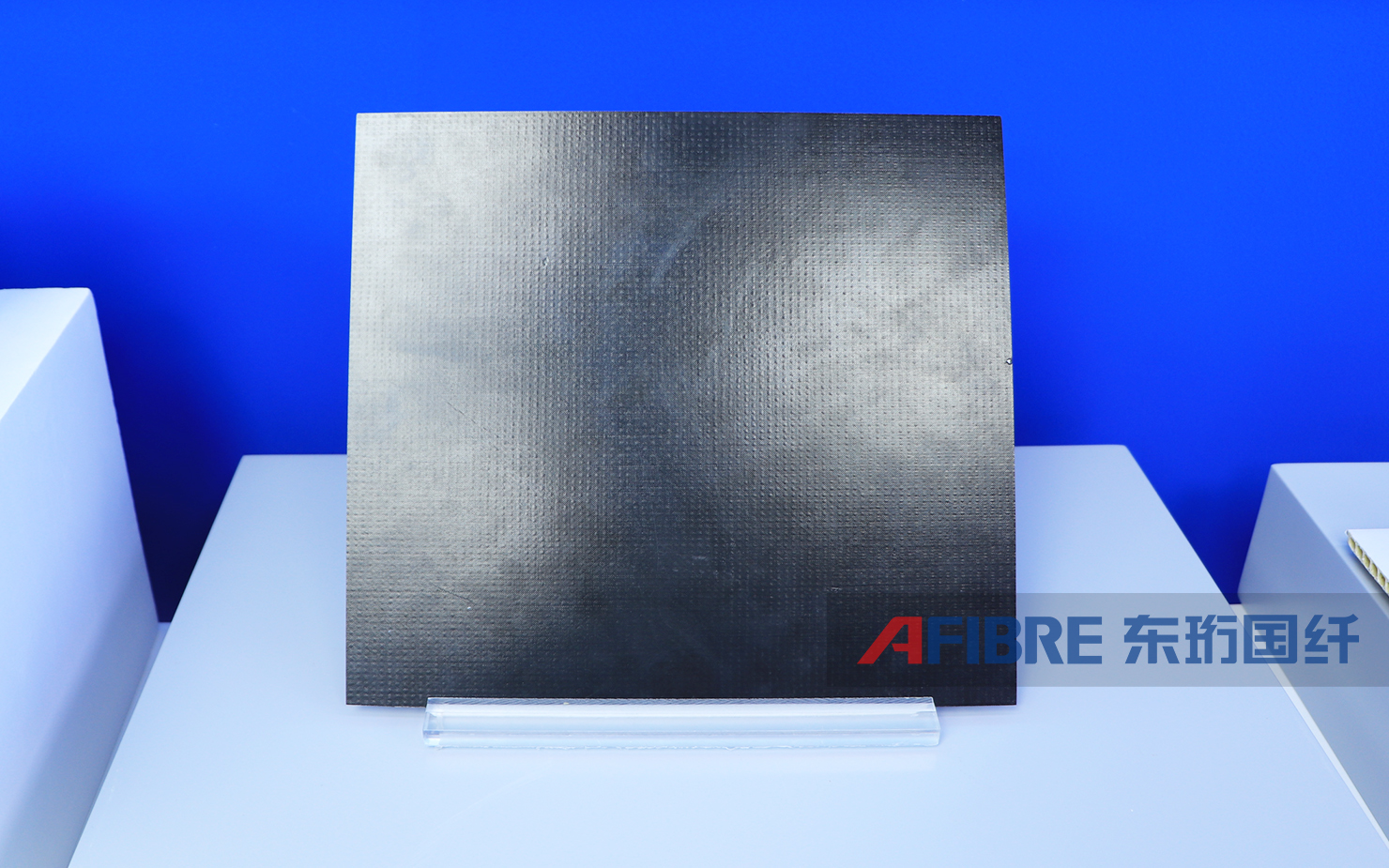

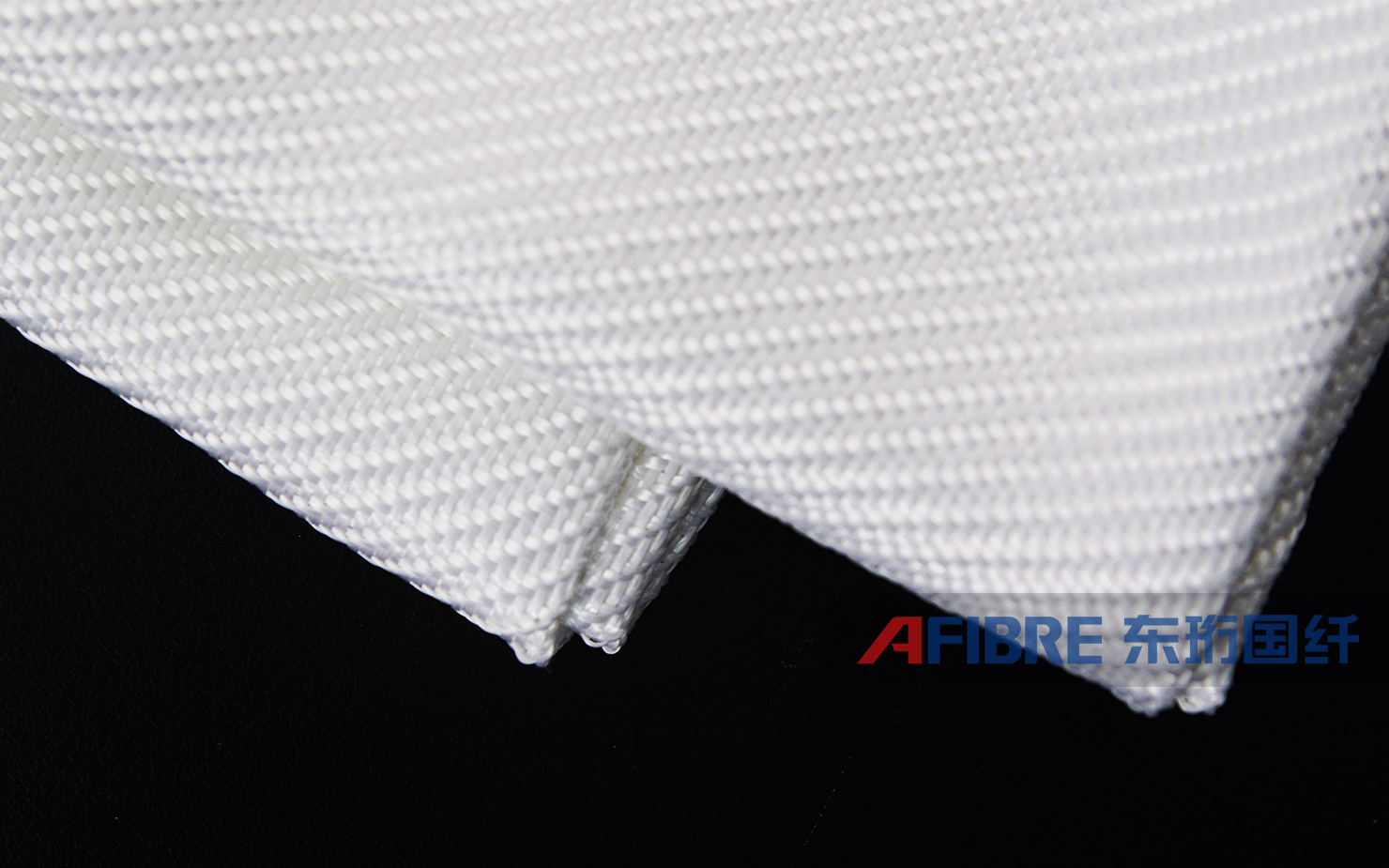

alumina fibre composite

The physical and chemical properties of the alumina fiber composite are stable, and the designability is strong. When making the composite battery shell, the fireproof layer is added into the integrated molding, and the sealing performance is good. The

95type-M Polycrystalline Alumina Fibre

◇ Chemical composition: AI2O3: SiO2 (%) > 95: < 5

◇ Mineral structure: γ

◇ Classification temperature (℃): 1100 ℃

95type-N Polycrystalline Alumina Fibre

◇ Chemical composition: AI2O3: SiO2 (%) > 95: < 5

◇ Mineral structure: α

◇ Classification temperature (℃): 1800 ℃

Alumina continuous fibre

Alumina continuous fibre is mainly composed of alumina and silica, and is prepared by the "sol gel" process. It can be used for a long time in a high temperature environment above 1000 ℃