TypicalapplicationsTypical Applications

- 01

Raw materials for downstream products: alumina short fibre can be used at 1200 ℃ - 1800 ℃, and its fibre products (such as fibre blanket, felt, paper, module, profiled parts, etc.) have low density and thermal capacity, low thermal conductivity, and good thermal shock resistance. It can also be directly used as thermal insulation filling materials for high-temperature kilns, such as furnace side wall, furnace top, furnace door, etc., and can also be directly used as thermal insulation and sealing for high-temperature components.

- 02

Filter material: alumina short fibre has high service temperature, good thermal shock resistance and chemical corrosion resistance, and is suitable for making high-temperature filter materials, such as candle filter, fabric filter and composite filter. It can be widely used in smoke suppression and dust removal of thermal power plants, metal smelters, chemical plants and diesel engine exhaust gas treatment systems.

- 03

Catalyst support: 95 type active gamma( γ) The alumina content in the phase alumina short fibre is up to 95%, with fine fibre diameter, high specific surface area, low internal control diffusion resistance and higher metal dispersion. It is a kind of fibre with less slag balls, white, soft and elastic. The fibre has much higher catalytic activity and good sulfur and heat resistance than granular alumina and other heat-resistant fibre carrier catalysts in the combustion of trace propylene and methane. At present, the fibre has been successfully applied in the field of catalytic combustion. Compared with other fibre supported catalysts, the reaction speed of methane can be increased by 3-8 times, and the reaction temperature required for methane conversion is greatly reduced.

- 04

ACCR composite core wire: the aluminum oxide continuous fibre (AF19) is embedded into the aluminum alloy wire, and the mechanical and electrical properties are far better than the steel core. The ACCR composite core can reach 8 times the breaking strength of the same aluminum wire, its weight is only 1/2 of the same volume of steel core, its linear expansion rate is less than 1/2 of the steel core, and its conductivity is much higher than that of the steel core.

- 05

High-temperature resistant parts: the sleeve woven with aluminum oxide continuous fibre has multiple characteristics such as high temperature flame retardance, good flexibility, large elasticity, easy processing, good insulation, etc. It has good strength at 1200 ℃ and above, and is widely used for cable fire protection.

- 06

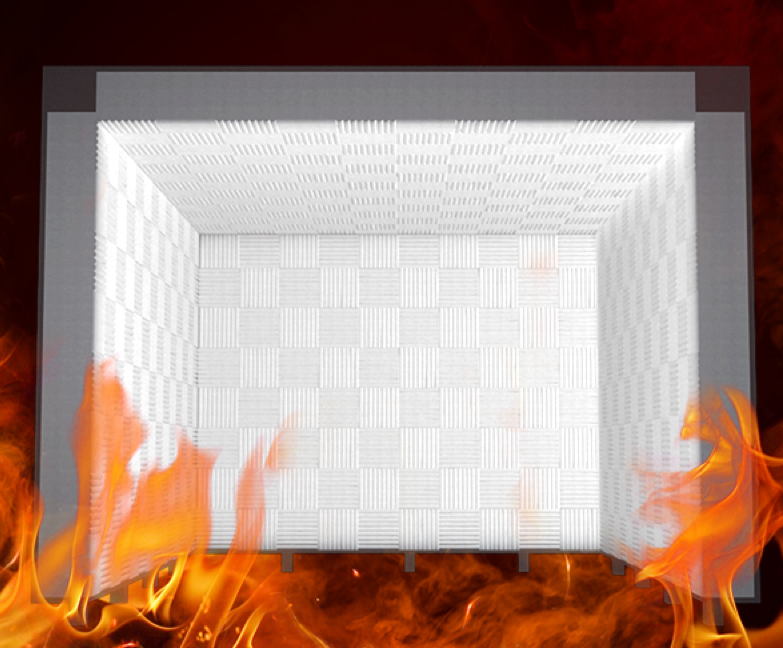

High-temperature heat insulation material: the braidability of alumina continuous fibre makes it suitable for special connection of heat insulation parts and three-dimensional braided parts, and also can be used as lining heat insulation material in metallurgical furnace, ceramic sintering furnace or other high-temperature furnace. Its low density, good thermal insulation and small heat capacity can not only reduce the mass of furnace body, but also improve the accuracy of temperature control, with significant energy-saving effect.

- 07

Chemical corrosion resistant material: alumina continuous fibre, with its excellent corrosion resistance, can effectively meet the high temperature filtration in pressurized fluidized bed combustion combined cycle (PFBCC) and integrated gasification combined cycle (IGCC) power generation technology.

ApplicationadvantagesApplication advantages

-

01

Alumina fibre has the advantages of low slag ball content, good strength, low thermal conductivity and high temperature resistance, and its products are widely used in thermal insulation fields such as high-temperature kilns.

-

02

Alumina fibre board is made of alumina fibre and finally formed by beating and stirring, vacuum filtration, demoulding and drying, sintering and machining. Compared with fibre blanket, alumina fibre board is a rigid fibre thermal insulation product with supporting strength. It is hard in texture, excellent in toughness and strength, and has excellent wind erosion resistance. With low thermal expansion rate, light weight and convenient construction, it is an ideal energy-saving material for furnaces, pipelines and other thermal insulation equipment.

-

03

The fibre blanket and fibre paper prepared with alumina fibre as raw material can be fixed on the outside of the furnace door for sealing and heat insulation due to their excellent toughness. Alumina fibre paper is made by cutting and beating alumina fibre, adding corresponding binder and dispersant during the beating process, and finally forming. fibre paper can be cut into various shapes and used to make flange gaskets or other high-temperature insulation fields.

-

04

Chemical corrosion resistant material: alumina continuous fibre, with its excellent corrosion resistance, can effectively meet the high temperature filtration in pressurized fluidized bed combustion combined cycle (PFBCC) and integrated gasification combined cycle (IGCC) power generation technology.